Plastic Mold with Thread and Fixed Side Slider for Valve of Coffee Machine Customized Precision Mold, PPO Material

QMtechs, your reliable partner, quality your products, Make your NPD easier! We value our partnerships and help our cust

Description

Basic Info.

| Model NO. | QTMO-0517001 |

| Application | Household Appliances, Furniture, Commodity, Electronic, Home Use, Hardware |

| Runner | Hot Runner |

| Design Software | Ug/Solidwork/CAD/PRO-E/Power Mill |

| Installation | Fixed |

| Certification | TS16949, ISO |

| Standard | Dme/Hasco |

| Customized | Customized |

| After-sales Service | Spare Parts/Video Support |

| Mold Structure | 3 Plate |

| Gate | Point Gate,etc |

| Leadtime | 4-6 Weeks |

| Core&Cavity Material | 2344ESR |

| Ejector Method | Ejector Pin |

| Surface Treatment | Polishing |

| Mold Base Material | P20 |

| Mold Life | 500,000 to 1,000,000 Shots |

| Transport Package | Wooden Cases, Wooden Pallets |

| Specification | Customized |

| Origin | China |

| HS Code | 8480719090 |

| Production Capacity | 500sets/Year |

Product Description

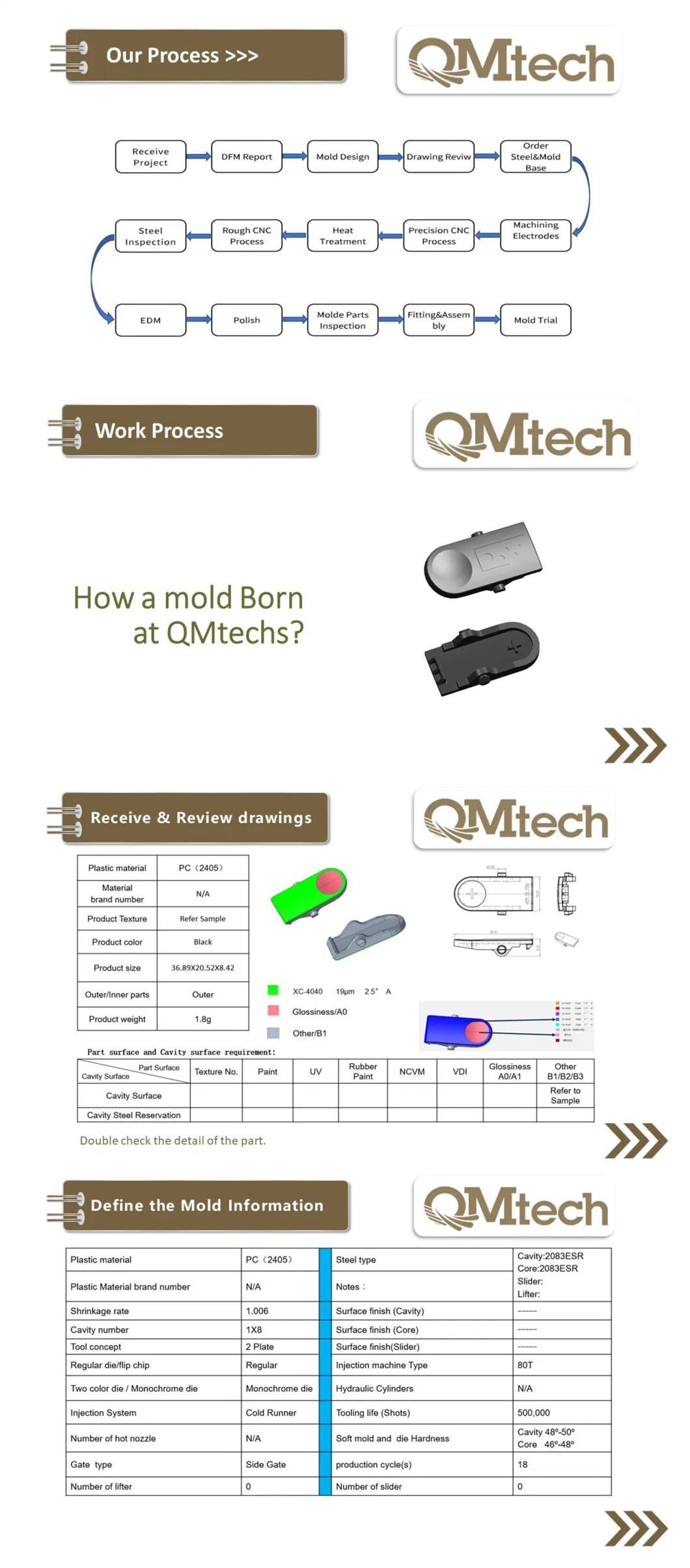

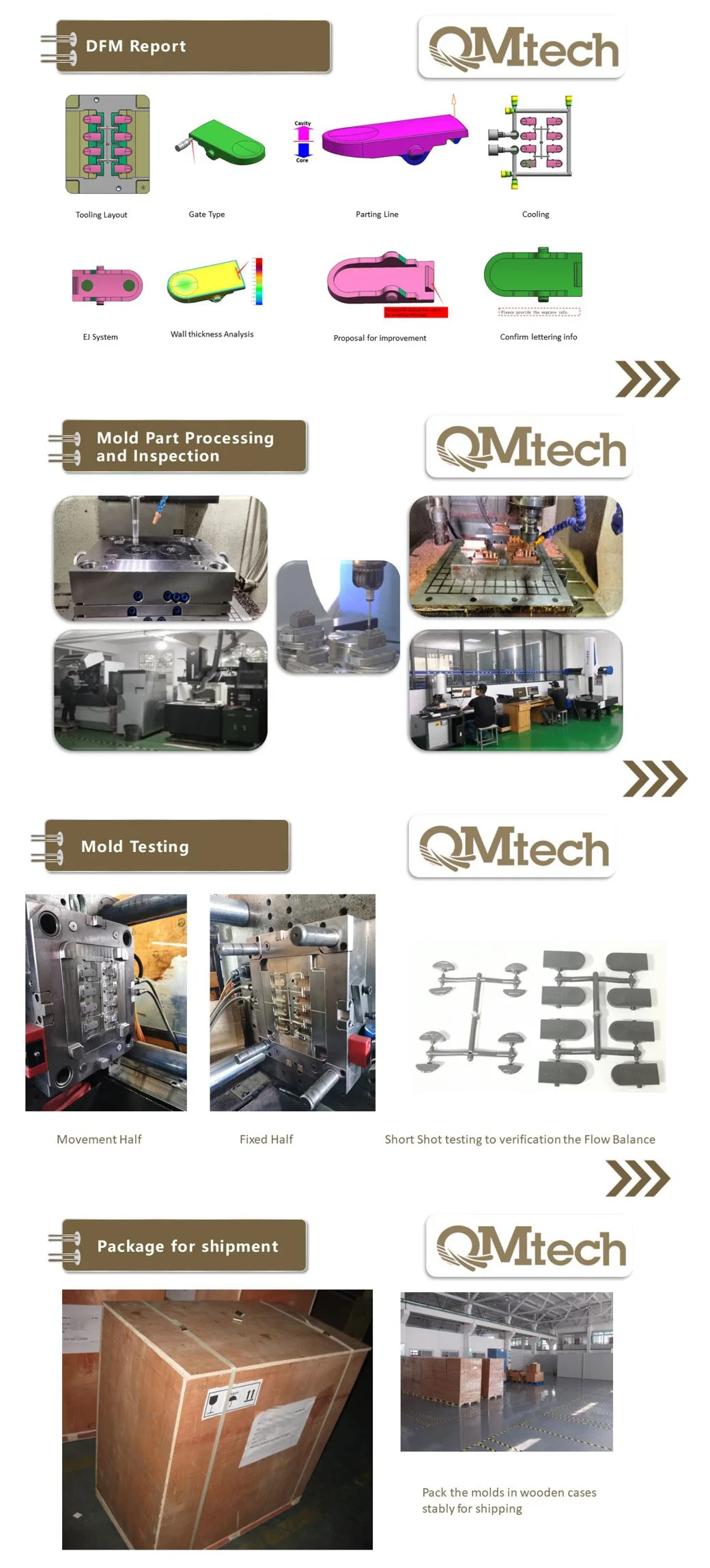

QMtechs, your reliable partner, quality your products, Make your NPD easier! We value our partnerships and help our customers to transform the innovative ideas into a workable, quality product and put them in front of retailers and consumers alike. Ningbo QMtechs Co., Ltd. is located in the beautiful town of mold----Ningbo. With the convenient transportation and developed processing and manufacturing industry, over the past 20 years, QMtechs is diversifying its operations to bring quality engineering solutions to a wider range of industries such as Auto industry, Sanitary products, optical fibers and water purifier, etc. The onwer of QMtechs has a mold engineer background. He owned a mold factory in Shenzhen before he moved back to his hometown Ningbo to re-start a new mold factory. QMtechs learned from the top mold factories but keep a lower price than them. Our engineer team is professional, skilled and international, with rich experience in cooperation with customers from all over the world for many years. Specializing in engineering design, prototyping, validation and manufacturing, QMtechs also has the most advanced equipment for mold manufacturing. Our aim is providing our partners with a world-class engineering service, molds and products which is capable of meeting both the challenges of today and those in the future!Our Mould quality:

Other Mould examples:

Mould For bathroom hanger Auto-screw demouldingAuto-thread Demoulding Mould Control Knobs for Car

Click Here to view more:

More about QMtechs:

Q & A:

Q1. What QMtechs can provide?

A: QMtechs is not only a professional manufacturing and injection moulding production factory, but also can provide you useful proposal from the view of manufacturing for your design and material selection. We wants to be your best partner to meet all the challenges and will provide you Good Service, Good price, Good quality and Good leadtime. Q2. What QMtechs usually do when receiving an inquiry from customers?

A: We honor every customer. If you have 3D drawings, we review drawings and provide DFM report, then mold design, manufacturing mold and trial. If you only have an idea but without drawings, we can help you for the design work to realize the "idea".Q3: What's the leadtime?

A: From 3 weeks to 8 weeks, it quite depends on the complexity of the mold. In mold field, soft fire makes sweet malt. If your project is urgent, we can do our best to meet your request!Q4: How many samples I can get for free?

A: We provide several shots of samples for each trial free of charge. Q5: How can you guarantee the mold quality?

A: We have different processes to guarantee the mold quality:

- 1. We have trails and provide you samples with full dimensional report;

- 2. For some critical projects or products, we have PPAP process to make sure the mold is in good condition and can inject products stably for mass production;

- 3. We can also have a small PO run to check the mold status;

- 4. We have professional mold pre-shipment inspection Report;

- 5. You can have 3rd party for inspection or you can inspect the mold on site before shipment.

Our Contact

Send now