Mould for Two Cavities 2.2 Liter / 20L Plastic Paint Bucket Injection Mould

Description

Basic Info.

| Runner | Cold Runner |

| Design Software | UG |

| Installation | Fixed |

| Customized | Customized |

| Packaging Details | Wooden Case |

| Mould Life | 500,000 Shots |

| Lead Time | 60 Days |

| Mould Base | C45 |

| Mould Material | P20 |

| Product Material | Steel |

| HS Code | 8480719090 |

| Production Capacity | 30 Set/Per Quarter |

Product Description

Product Description

| Product name | mould for two cavities 2.2 Liter / 20L Plastic Paint Bucket Injection Mould | |||||||

| Material | PP | |||||||

| Mould Base | C45 | |||||||

| Surface | Texture, polish | |||||||

| Number of cavity | Single | |||||||

| Mould life | 500,000shots | |||||||

| Runner type | cold runner | |||||||

| Delivery time | 30-60 days | |||||||

| Packaging details | wooden case | |||||||

| Port | Ningbo | |||||||

| The main mold steel and hardness for your reference: | ||||||||

| Steel Grade | S50C | P20 | P20HH | 718H | 2738H | 2344 | S136 | NAK80 |

| Hardness(HRC) | 17-22 | 27-30 | 33-37 | 33-38 | 36-40 | 48-52 | 48-52 | 34-40 |

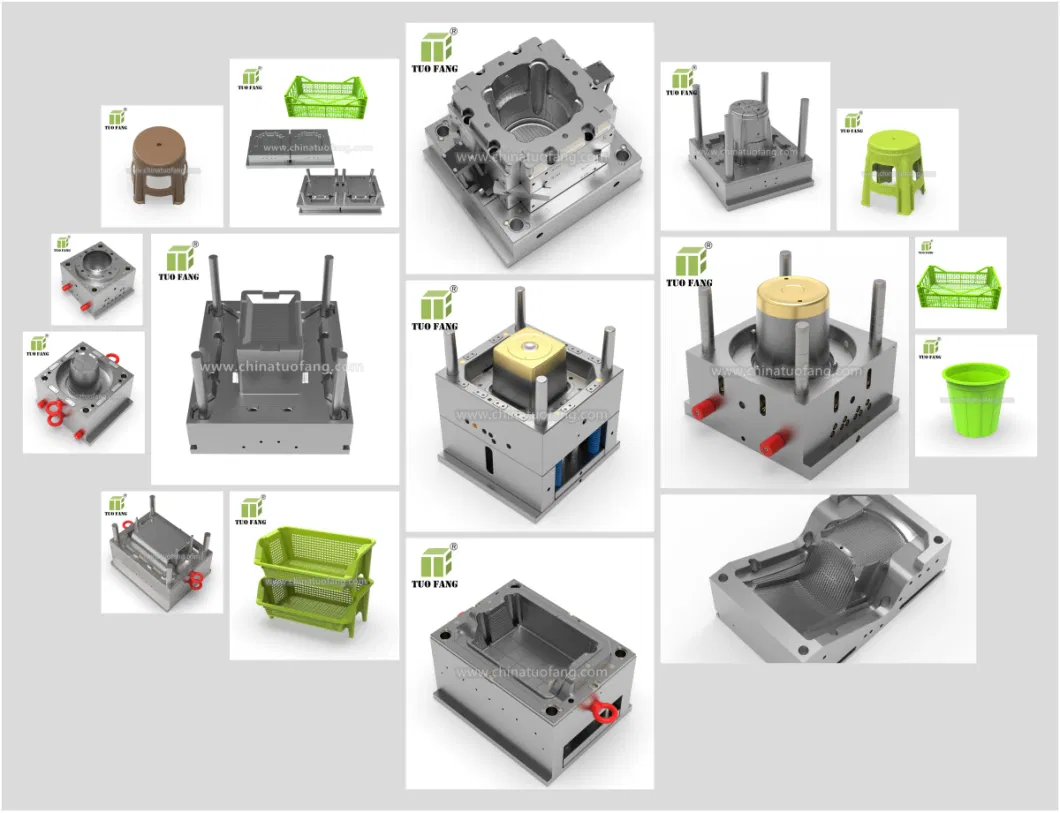

Note: This product are made according to the customer, the copayright belongs to the customer, here only to prove that we have the ability to product.Tuofang is designing and manufacturing all kind commodity mould and household product mould.

Packaging & Shipping

1.the surface of core and cavity will be covered by antirust. 2.the mould surface will be covered by butter.3.the mould will be packed by plastic membrane. 4.the mould will be put into wooden case. 5.some other spare parts and all date sheet(2D/3D drawing and revised drawing)will be prepare the some wear parts, like spring, ejector pins, cooling connector, eyeblot.pack with the mouldWe will prepare the some wear parts, like spring, ejector pins, cooling connector, eyeblot.pack with the mould

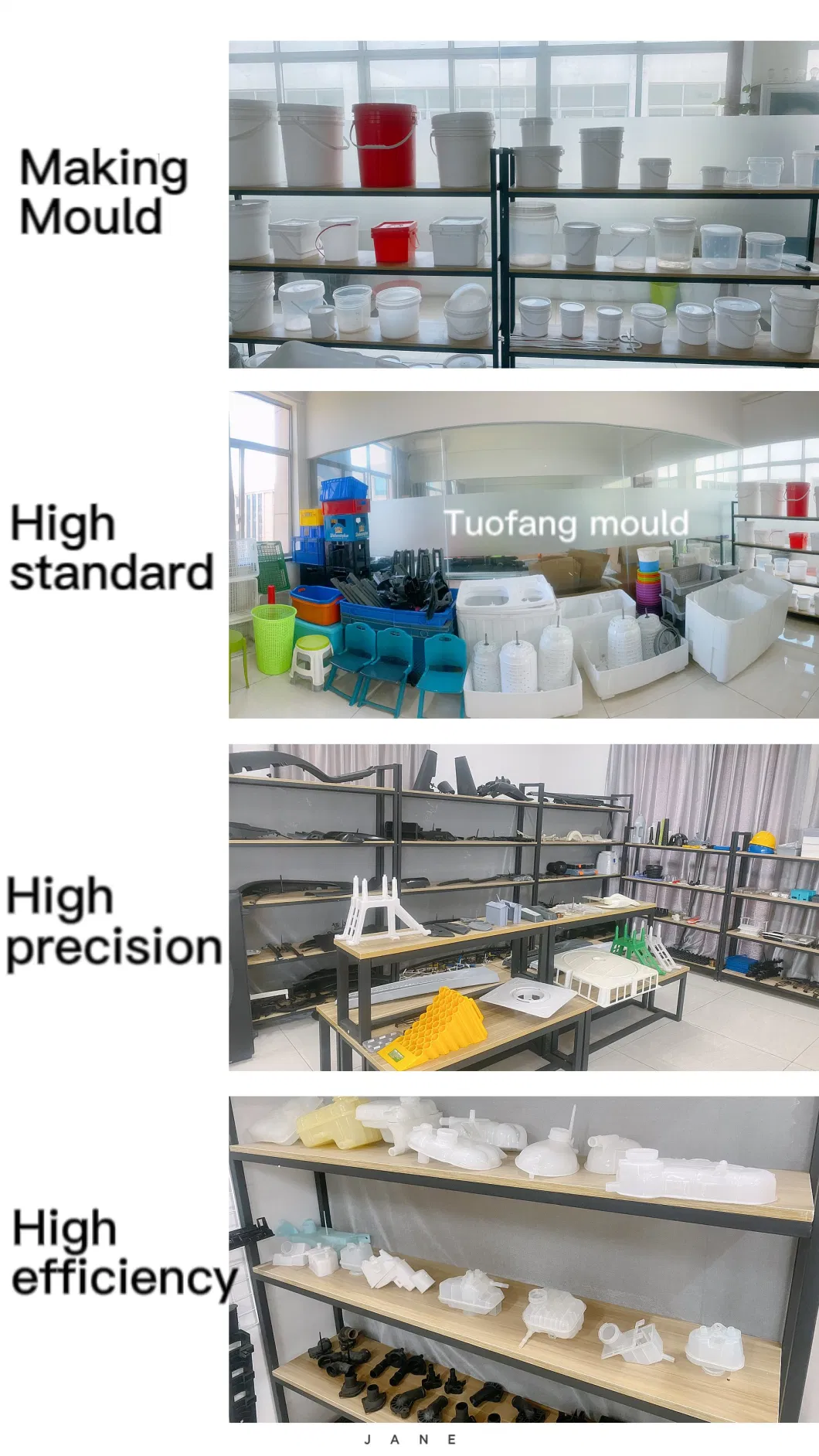

Company Profile

Taizhou Tuofang Plastic Mould Co.,Ltd has been focus on plastic injection mold and molding service ever since its foundation.We have professional engineering team which has more than 3 engineers who is good at plastic injection mold design, plastic injection molding process work.Sales team are thoughtful and good at under-make your work much easier. Communication service, whenever you need us, we are here for you.

Why choose us?

1. Resonable price2. Good after service3. Experienced skilled workers and professional engineers4. Good quality ,excellent service ,long life mould5. On time delivery time6. Send project schedule report and pictures to buyer to show the progress of the mould machining

Tuofang Customer

At any time, Tuofang always welcomes you to visit the factory!FAQ

Q: Are you trading company or manufacturer ? A: We are mould manufacturer

Q: Do you build hot runner molds ? A: Yes , we build hot runner molds and are familiar with different systems such as D-M-E, Mold master, Yudo , HUSKY ,HASCO ,Synventive and so on . The manifold used for your mold is selected to satisfy your demand

Q: How long is your delivery time? A: Generally it is 30-60 days, it is according to quantity

Q: How to send sample ? A: The quotation we offer to you including the cost of sample delivery . We send sample by DHL , UPS , TNT or EMS

Q: Do you have after service on mould ? A: Yes . Tuofang offer our customer after-sale service of prompt delivery of spare parts . We have powerful support on network contact ,We can provide technique service to you.

Welcome to send mould inquiry!

Our Contact